Tank 32001 at Sunoco LP’s fuel distribution terminal in Linden, New Jersey, is unremarkable in its surroundings. It’s 56 feet (17 meters) tall and 202 feet (61.6 meters) in diameter, one of hundreds just like it along the Chemical Coast across Arthur Kill from Staten Island.

But for all its apparent normalcy, it plays a critical role in the carefully calibrated gasoline distribution network fueling greater New York.

It’s just one tank at one terminal, but the compounding consequences of an unplanned outage or, worse still, a failure, cannot be overstated.

That’s why the outages that are planned must be methodical, purposeful, and—ideally—brief.

Tank 32001 was due for inspection per API 653 in early 2023. The inspection revealed that the interior lining was failing, and refurbishment was in order. Strong teamwork, technology, and the right lining products from Carboline combined for a successful refurbishment despite tough conditions and the owner’s tight deadline.

Scope of work tackles pitting and wormhole corrosion

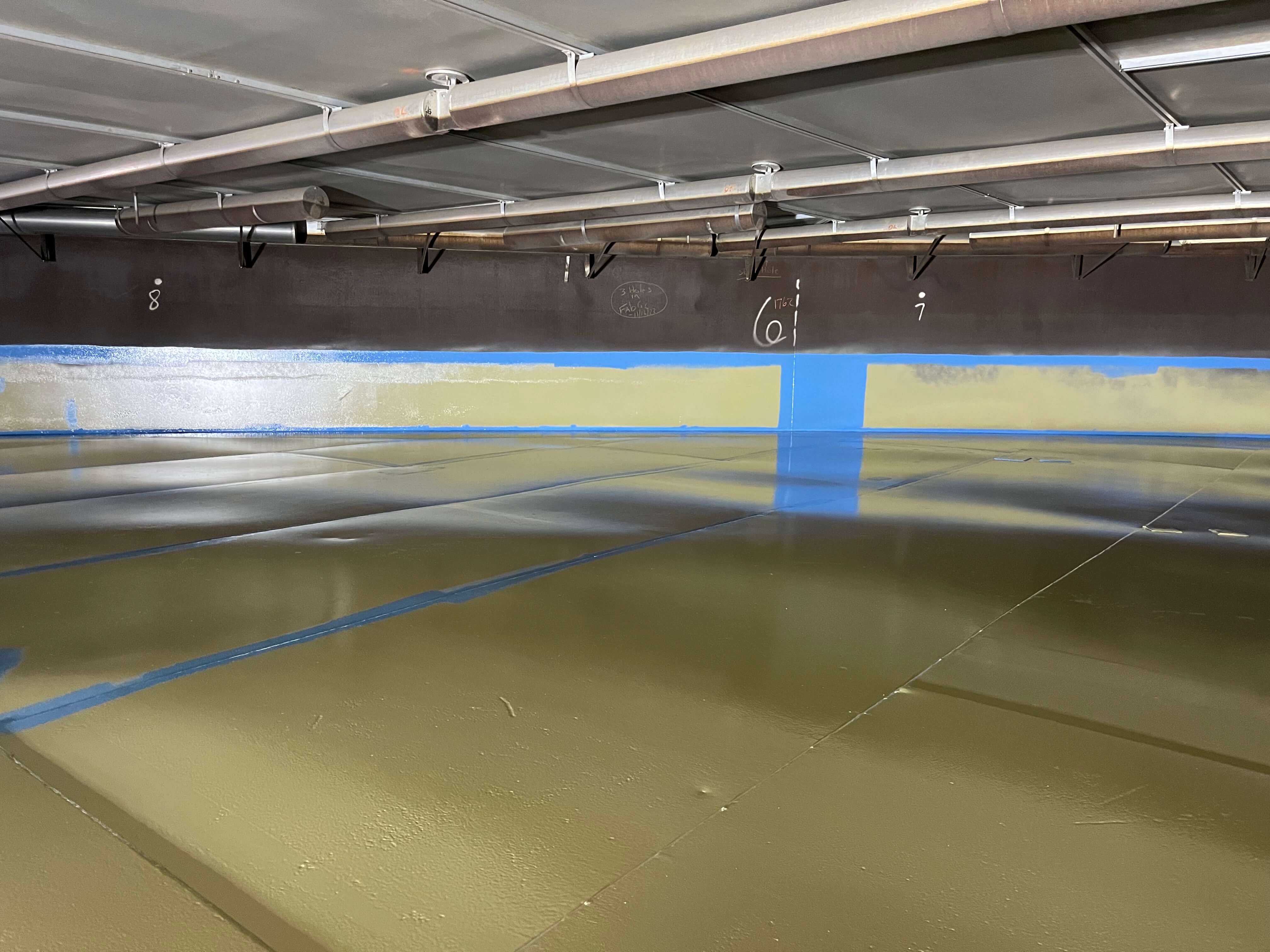

Visual inspection inside Tank 32001 revealed its interior lining was failing, and pitting and wormhole corrosion was apparent across large areas of the steel. This corrosion was widespread but not severe; inspectors regarded it as normal for its immersion service.

The scope of work for this refurbishment consisted of:

- • Decontamination of the substrate via solvent cleaning per SSPC SP-1

- • Abrasive blasting via coal slag media of the interior floor of the tank as well as the lower two feet of its shell, including manways and structural steel supports, to SSPC SP-10

- • Application of thinned Phenoline 311 as a holding primer

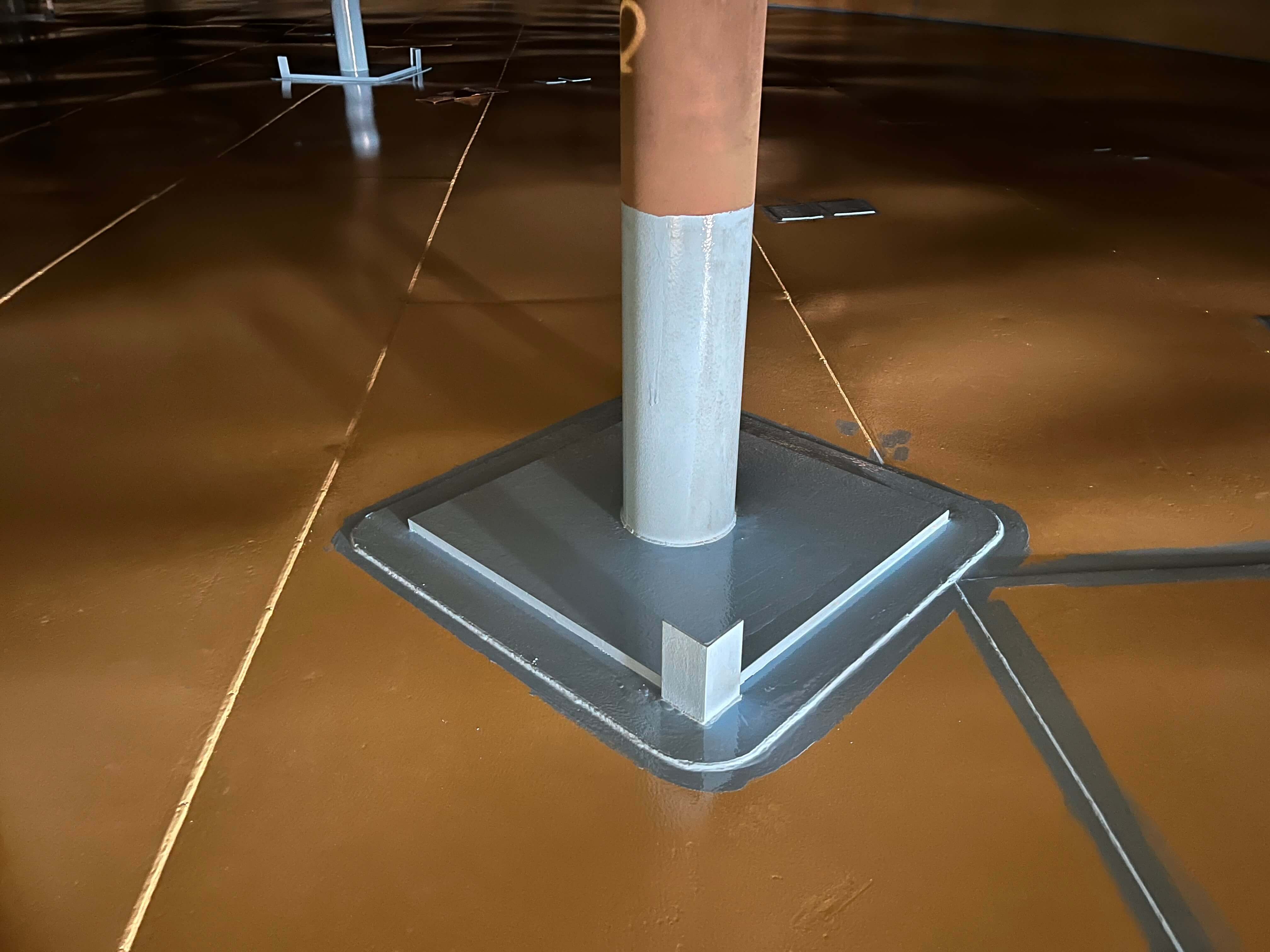

- • Application of Phenoline Tank Shield FP to fill in areas impacted by pitting

- • Stripe-coating weld seams, corners, and edges with thinned Phenoline Tank Shield

- • Application of Phenoline Tank Shield as the finish coat

As you’ll see in the next section, two prevailing factors influenced the coating contractor’s surface preparation decisions and guided Carboline’s specification of the lining system.

A clock ticking despite cold weather

Work began in early February 2023, the coldest part of the year in New Jersey.

Though the painting contractor and the owner each knew the challenges associated with cold weather, time was still of the essence. Sunoco LP needed as rapid a turnaround as feasible to minimize downtime and return to maximum storage capacity.

Aware of the owner’s push for a fast turnaround, the painting contractor suggested bringing a BlastOne International Vertidrive M3 remote blaster to the site. Sunoco LP was aware of the remote blaster’s capabilities and eagerly agreed to deploy it.

This turned out to be a wise move. Carboline technical service personnel detected shadowing on some areas of the substrate which indicated parts of the prior lining remained after an initial blast. Re-blasting could have slowed progress, but the combination of manned and remote abrasive blasting kept this phase of the work on-schedule.

After satisfactory inspections following blasting, the lining system could be applied:

Phenoline 311 Primer is an ideal holding primer for interior tank relines and uniquely suitable in this specific case: It cures down to 20°F (-6.7°C), well below the lowest temperature measured during the project. It also boasts a fast recoat time (one hour at 50°F/10°C or two hours at 35°F/1.7°C), which was important for a customer who demanded a rapid turnaround.

Phenoline Tank Shield FP (the FP stands for "flow primer") is a solvent-free epoxy specifically designed for filling pitted steel. It is formulated with ideal flow properties to completely wet-out and fill surface voids. Its low-odor properties are critical when working in enclosed spaces, as is its ability to apply down to 35°F (1.7°C). Temperatures did dip that low the day Phenoline Tank Shield FP was applied, so the contractor applied it via back-rolling instead of spraying according to guidance from Carboline.

Phenoline Tank Shield, like its FP variant, is a solvent-free epoxy ideal for a wide range of fuel exposures. This low-odor product can also be applied down to 35°F (1.7°C), which was critical for this project. In addition, Phenoline Tank Shield comes in a batch mix formulation so plural-component spray application is unnecessary. Faster, simpler application of the lining was crucial under a tight project timeline.

Tank 32001 returns to service

Following application of the lining system, routine visual inspections, DFT tests, holiday tests, and cure tests were conducted. Some light remediation was necessary to address pooling and sagging of the lining product; this was performed without issue.

Because product selection emphasized cold weather application and fast recoat times, Sunoco LP returned Tank 32001 to normal service toward the end of March 2023, less than eight weeks after taking it offline.

This refurbishment project illustrates how industrial asset protection is as invaluable as it is seemingly invisible.

It was just a big white tank, one of hundreds just like it on the Chemical Coast. But its new lining is expected to last two decades, protecting the integrity of the tank and its essential contents.

The mark of this job well-done will be what doesn’t happen. No unplanned outages. No missed fuel deliveries. No customer crises. Only life and commerce carrying on.